Kaeser – Compressed Air System Basic Models: The SXC “Compact” Series

The all-in-one compact compressed air package

Compressed air systems (*) of the SXC series have been designed by Kaeser for trades and crafts. On only 0.62 m², they comprise all components necessary for air supply under a single strong polyethylene cover: a rotary screw compressor with SIGMA-Profile, a refrigeration dryer and an air receiver.

Compressed air systems of the SXC series are offered with these performance data:

Pressure: 8, 11 or 15 bar

Flow rate range: 0.26 – 0.80 m³/min

Your advantages

- Connect and go:

Piping and installation of our integrated packages takes little time. Simply connect this compact compressed air package to the power supply and compressed air distribution network and you’re ready to go – that’s it! - Protection from corrosion damage:

Thanks to the integrated refrigeration dryer, the SXC package delivers high air quality and protects your tools and equipment from corrosion damage. - Simple maintenance:

All maintenance and service points are easily accessible once the SXC’s removable enclosure which is made of rotational moulded polyethylene is effortlessly lifted away. The electronic condensate drain can be inspected via a grille. Maintenance is simple and effective.

Equipment

Complete unit Ready-to-run

Ready-to-run

Fully automatic

Super silenced

Vibration-damped

Double-skinned rotational moulded polyethylene enclosure

Optimal accessibility of all service points after cover removal

Sound insulation

Sound enclosure

Anti-vibration mounts

Dual anti-vibration mounts

Electric motor

Energy-saving motor (IE3)

Quality German manufacture

IP 54

Insulation class F for greater power reserve

Rotary screw airend

SIGMA Profile rotors require approximately 10 to 20 percent less energy than conventional rotors of the same air delivery capacity.

V-belt drive

Maintenance-free belt

No re-tensioning

Fluid and air flow

Honeycombed dry air filter

Inlet with check valve

Pneumatic venting valve

Cooling fluid tank with separately installed separator cartridge

Pressure relief valve

Minimum pressure/check valve

Micro-filter in the cooling fluid circuit

Cooling

Air-cooled

Aluminium cooler for cooling fluid with separate fan motor

Second fan on drive motor shaft

Automatic warm run control (only active at very low loads)

Receiver

Internally coated

Electronically controlled condensate drain

SIGMA CONTROL BASIC controller Electronic control and monitoring system

Electronic control and monitoring system

Icons

Large display

Start-Stop control

Monitoring of: Direction of rotation, system pressure, airend discharge temperature, refrigeration dryer

Measured data displayed: Network pressure, cut-out pressure, airend discharge temperature

Status data displayed: System state, active fault, maintenance due

Also displayed: Counter for service, load and operation hours

Adjustable service interval

Pressure and temperature unit selection (bar/psi/ MPa, °C/°F)

Individually reducible nominal system pressure

Emergency stop switch

“Motor running” floating relay contact

Electronic pressure transducer

Electrical components

Control cabinet to IP 54

Automatic star-delta contactor combination (above 3 kW)

Overcurrent trip

Control transformer

Refrigeration dryers

Control cabinet to IP 54

Automatic star-delta contactor combination (above 3 kW)

Overcurrent trip

Control transformer

Contains fluorinated greenhouse gas R-513A

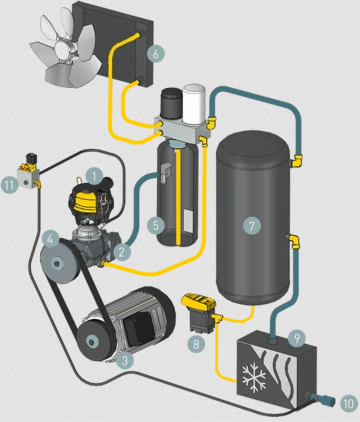

SXC component layout

- Air filter

- Airend

- Drive motor

- Automatic belt tensioning

- Fluid separator tank

- Cooler

- Air receiver

- ECO DRAIN condensate drain

- Refrigeration dryer

- Compressed air outlet

- Control valve

Product PDF : Kaeser – SX8